Cerium Oxide and Glass Polishing

Cerium Oxide is an oxide of the rare-earth metal cerium and is commonly used in glass fabrication and restoration facilities that focus on high degrees of clarity for finished glass products.

How to remove light scratches from glass using cerium oxide

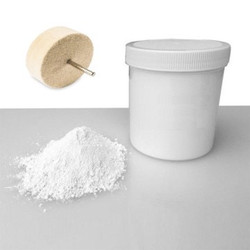

Removing scratches in glass is a common request here at Ontario Glazing Supplies that we often field questions about with respect to aquariums, terrariums, glass furniture, home windows, and auto windshields. The most important thing to note is that if the scratch is deep (i.e. you can feel it with your fingernail), almost always you will have no luck in removing the scratch and require replacing the glass to rectify the problem. However, if the scratch is surface level and very fine (i.e. hairline), many customers have had success with our cerium oxide foam paste, a felt polishing pad , and a standard hand-held power-drill. For more information consult the product pages.

NOTE: Care must be taken to ensure the amount of friction applied to the paste is not excessive to the point where the paste dries out.

How to polish glass using cerium oxide

In glass fabrication facilities, almost always during the final steps of automated production cerium oxide is combined with heated water (at least 80°F / 30°C) to form a slurry and this slurry is used in combination with a felt pad or polishing wheel to remove surface level scratches and improve the clarity of the glass.

The superior suspension properties exhibited in high quality cerium oxide compounds provides ease of maintenance and cleaning due to soft settling and facilitates reuse in modern recirculation systems. The efficiency of the polishing process relies heavily on the concentration of cerium oxide and water that forms the slurry and temperature.

A hydrometer is used to measure the relative density of the cerium oxide slurry on the concept of buoyancy in Degrees Baume. For light surface cleaning applications such as pre-silvering, 1° Baume is ideal, while beveling and edging call for a higher reading, typically between 3 – 5° Baume.

The temperature of the slurry should be maintained between 32 – 40°C (90 – 105°F) for optimal performance.

NOTE: Your exact requirements require independent research and calibration to ensure your production line is performing optimally.

Conclusion

Whether you’re a DIYer looking to buff out a few minor scratches on your paludarium or a company focused on the fabrication of glass and or IG units, cerium oxide might be a product that helps ensure your glass is polished, clear, and ready for prime time.

Canadian Dollars

Canadian Dollars

US Dollar

US Dollar

Mexican Peso

Mexican Peso

Euro

Euro

British Pound

British Pound

Australian Dollar

Australian Dollar